Plating a substrate will enhance and protect the part making it more resilient and less prone to corrosion over time. There are many plating techniques available. Which technique you choose is dependent on your desired effect and application of the part being plated.

In this article will be addressing the difference between electro-plating and electroless plating processes. So, what IS the difference between electro plating and electroless plating?

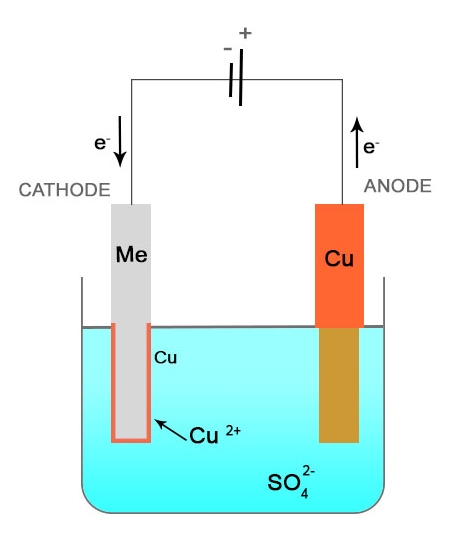

The simple answer is that electro-plating uses electricity in the process of transferring a deposit to a substrate while electroless plating utilizes an aqueous solution and no electricity to transfer the deposit.

The Electro Plating Process

The electroplating process utilizes a battery or rectifier to supply an ionic metal with an electric charge. This charged metal is then deposited on a substrate to form a non-ionic coating.

The electroplating process utilizes a battery or rectifier to supply an ionic metal with an electric charge. This charged metal is then deposited on a substrate to form a non-ionic coating.

A common setup for this type of plating involves a chemical solution that contains the metal in an iodized form. A positive charge is supplied to the metal part via an anode and a negative charge from a cathode. This supplies an electrical current that shifts the chemical composition of the part and delivers a firm and resistant coating to the surface of the metal. You can reach desired levels of thickness through multiple applications.

Electro-plating requires careful procedures as it employs potentially dangerous equipment and complex filtration systems.

The Electroless Plating Process

Electroless plating process is much simpler as it use no electricity and requires no extra equipment. In the electroless plating process, the part or substrate receives it’s deposit via an auto catalytic reaction via a reducing agent. The reducing agent interacts with the metal ions making the deposition possible. The process is completed with an application of anti-oxidation chemicals with improves the parts resistance to corrosion and friction prolonging its life.

Mid Atlantic has been providing electro plating and electroless nickel plating services for over 40 years. We are dedicated to quality and precision. We service the aerospace, RF microwave communications sectors as well as the defense and medical fields.

Mid Atlantic has been providing electro plating and electroless nickel plating services for over 40 years. We are dedicated to quality and precision.

We service the aerospace, RF microwave communications sectors as well as the defense and medical fields.

Mid Atlantic Finishing Corp. is located in Capitol Heights Maryland and services the entire United States. MAF offers the following metal plating services nationwide:

Gold Plating Services, Silver Plating Services, Tin Plating Services, Tin-Lead Plating Services, Electroless Nickel Plating Services, Bright Nickel Plating Services, Sulfamate Nickel Plating, Copper Plating Services, Chemical Film Plating Services, and Precision Masking Services.

MAF is committed to the delivery of quality products to every segment of our customer base, a fundamental element of our Company’s Purpose and Mission.

MAF is committed to full compliance with all the requirements of NADCAP AC 7004; AC 7108.