by CITSaj | Jan 2, 2017 | Metal Plating, Microwave RF

Why We Need Metal Plating For The Microwave/RF Industry Wireless technologies continues to evolve. As a result, the need for well designed high-performing microwave subsystems has increased as well. This is where silver plating for microwave/RF industry comes into...

by CITSaj | Dec 16, 2016 | Metal Plating

Hydrogen embrittlement is when metals such as steel, become brittle and fractures. This happens when hydrogen is introduced into the metal substrate and subsequently diffused during the forming and finishing processes. Hydrogen embrittlement can seriously diminish a...

by CITSaj | Nov 26, 2016 | Electro Plating, Electroless Plating, Metal Plating

Plating a substrate will enhance and protect the part making it more resilient and less prone to corrosion over time. There are many plating techniques available. Which technique you choose is dependent on your desired effect and application of the part being plated....

by CITSaj | Nov 23, 2016 | Metal Finshing, Metal Plating

Electroless nickel plating offers numerous finish options. The finish you choose should be determined based on a variety of factors specific to your needs such as industrial application and desired properties on the finished part such as conductivity or magnetism. The...

by CITSaj | Nov 22, 2016 | Metal Finshing, Metal Plating

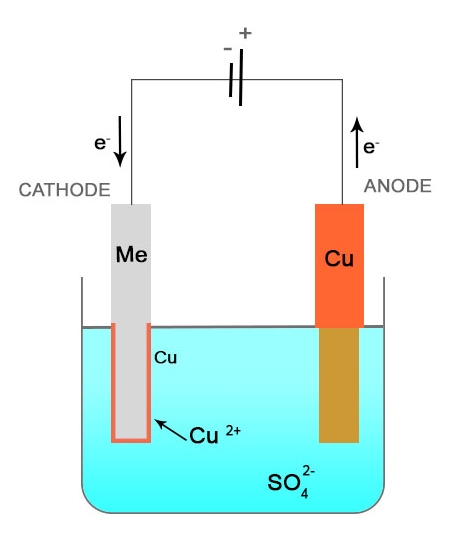

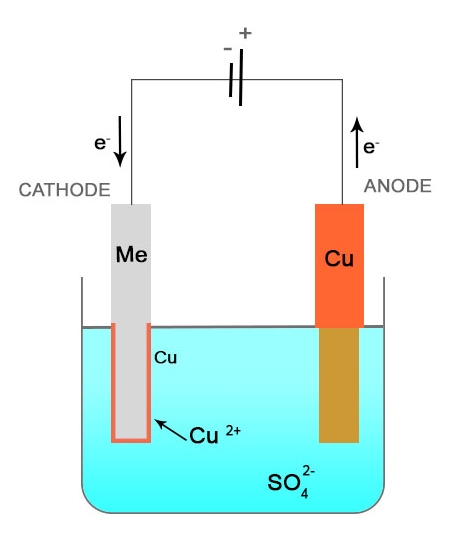

Nickel plating is another popular plating method used in industries such as aerospace, defense, RF and microwave communications sector as well as the medical field. Unlike EN plating, nickel plating is an electrolytical process which requires and electrical charge in...

by CITSaj | Nov 22, 2016 | Metal Finshing, Metal Plating

Electroless nickel plating, often referred to as (EN), is a process used for depositing a nickel alloy onto a substrate or surface without the use of electrical energy. Unlike electroplating, which does require a charge, the electroless nickel plating process involves...